Comprehensive Vision System Solutions for Automated Inspection

A vision system is a powerful technology that uses cameras and computer processing to automate monitoring, inspection, and quality control processes. Modern vision systems deliver high-speed analysis with superior accuracy compared to manual inspection, reducing human error and training costs while increasing operational efficiency across manufacturing and security applications.

Key Benefits of Vision Systems for Industrial Automation

Vision systems transform industrial operations by delivering:

- Enhanced Quality Control – Automated inspection catches defects that human inspectors might miss during long shifts

- Increased Speed – High-speed image processing analyzes products faster than manual inspection

- Cost Reduction – Minimize training requirements and reduce labor costs while improving consistency

- Real-Time Monitoring – IR cameras and thermal imaging enable temperature screening and safety monitoring

- Data Analytics – Collect inspection data for continuous process improvement

My Experience Implementing Automated Inspection at Vistronic Limited

I designed and implemented a comprehensive vision system for Vistronic Limited in 2004, with a significant CPU-based upgrade in 2013. This project increased inspection speed dramatically while requiring only 5-10 trained technicians to confirm inspection settings.

The solution included two distinct machine types:

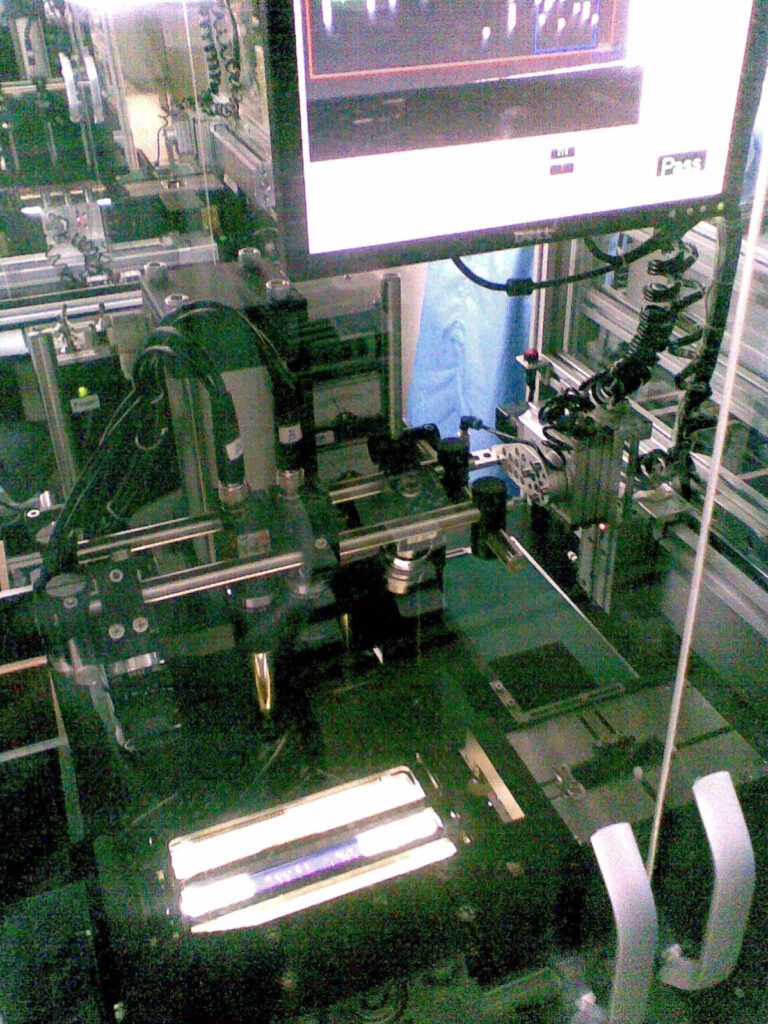

Automatic Inspection Machines – Fully automated workshop systems that process products continuously without operator intervention

Manual Inspection Stations – Operator-assisted machines that combine human judgment with vision system precision for complex quality checks

Vision System Applications and Advanced Features

Modern vision systems excel in multiple applications including defect detection, dimensional measurement, barcode reading, and pattern recognition. Learn more about machine vision technology and its industrial applications.

For related automation solutions, explore our engineering projects.

These automated inspection solutions provide manufacturers with unprecedented accuracy in quality control. The technology enables continuous 24/7 operation with minimal downtime, ensuring consistent product quality throughout the production cycle. Industries ranging from electronics manufacturing to pharmaceutical packaging benefit from these advanced inspection capabilities.

By implementing such technology, companies can significantly reduce waste, improve production efficiency, and maintain competitive advantage in demanding markets. The ROI typically materializes within 12-18 months through reduced labor costs, decreased error rates, and improved customer satisfaction.

Automatic inspection workshop

Standalone automatic machine

Inside automatic machine

Manual inspection machine with operator